Attachment:

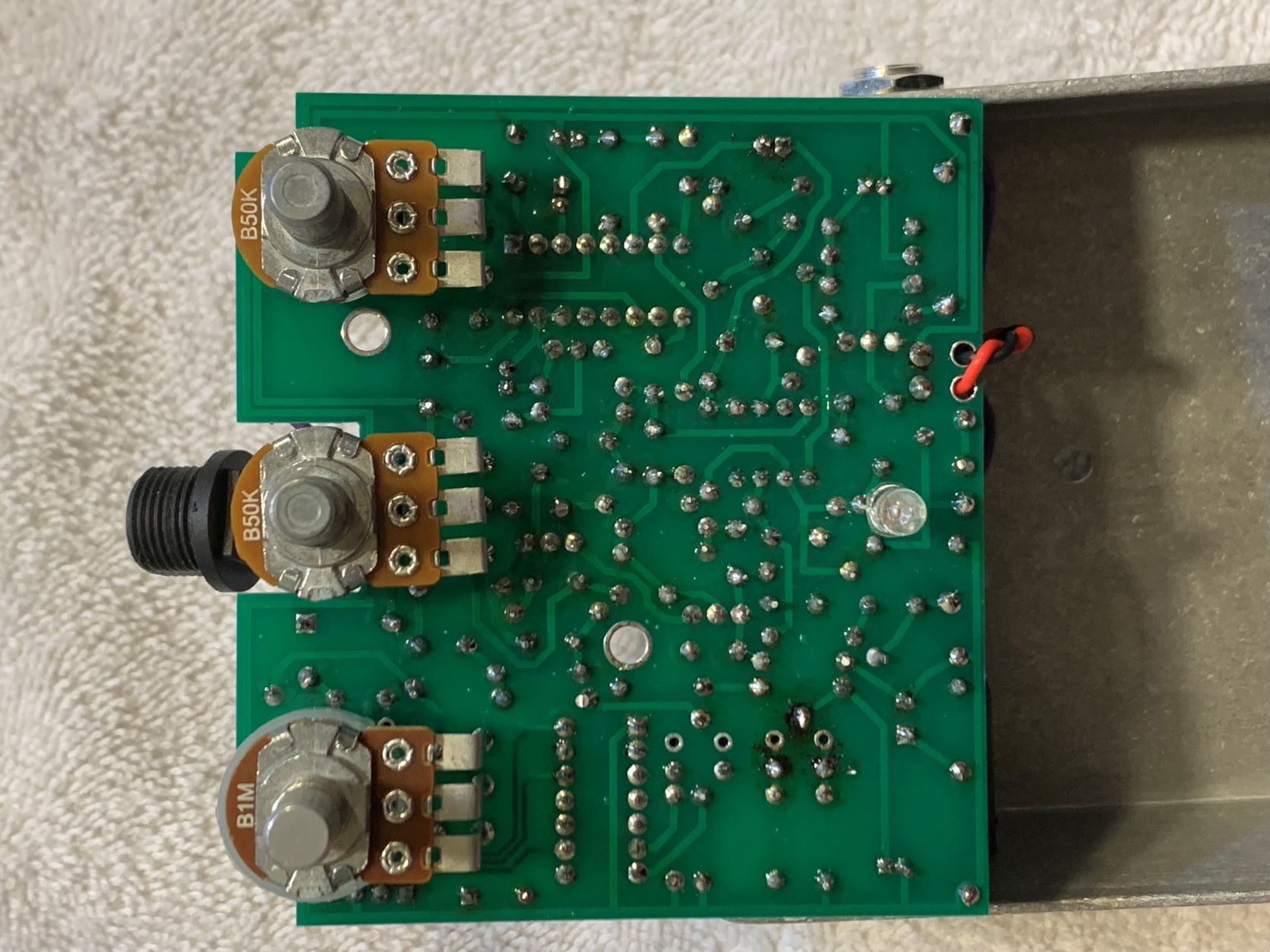

File comment: Solder side of PCB.

IMG-4990.jpg [ 262.59 KiB | Viewed 2672 times ]

IMG-4990.jpg [ 262.59 KiB | Viewed 2672 times ]

Attachment:

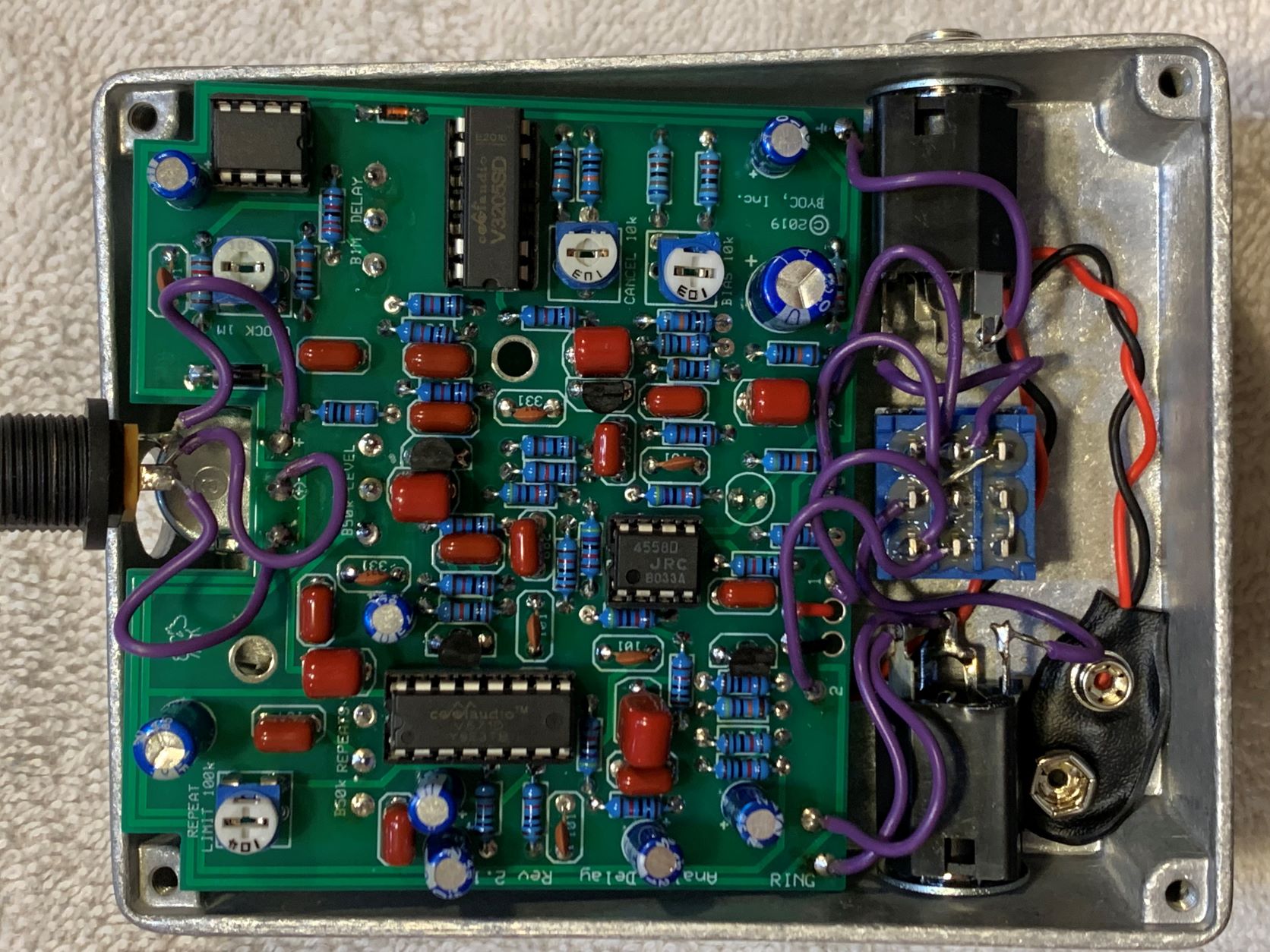

File comment: Component side of PCB.

IMG-4989.jpg [ 367.88 KiB | Viewed 2672 times ]

IMG-4989.jpg [ 367.88 KiB | Viewed 2672 times ]

The pedal passes dry signal whether the footswitch is engaged or not. The LED comes on when the footswitch is engaged. When the pedal is on, the pots and trimpots have no effect on the signal, it's just a dry signal the same as when in bypass. The pedal behaves the same when using a 9V battery as well as a 9V 100mA isolated power output.

I initially had some trouble with the bias trimpot (plastic part broke), and had to replace it, but this didn't resolve the issue. I had a bit of a hard time soldering when replacing the trimpot, but the connections appear to be good.

This is my 4th pedal build and I've never had any issues, but I don't know enough about circuit design or analysis to even know where to begin. I've double checked all the components for proper placement and orientation, as well as hookup wire connections and everything appears to be correct.

I have an old multimeter, though its functionality is quite questionable, but I don't know what to check, or how to check it.

Thanks!